Peter,

I'm not sure if your '63? 1000 has the cast steel one piece flywheel, or the one with a flex-plate & hub.

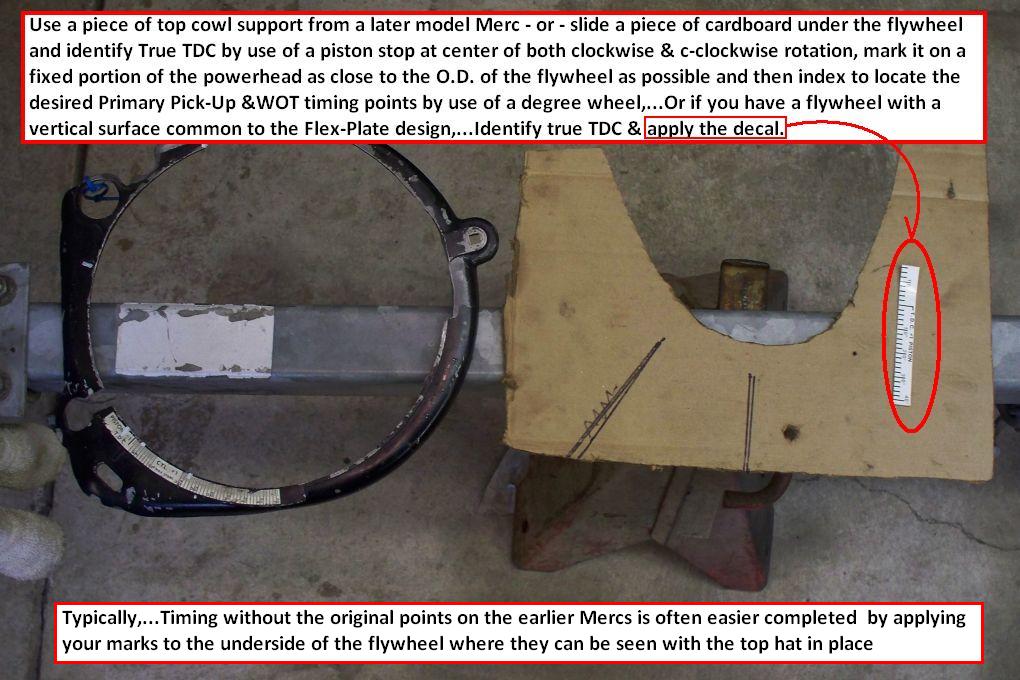

IF you have the cast steel flywheel (cast iron??) you will most likely find use of a later model top cowl support - or - a cardboard cut-out with a 360 degree dwell wheel the best way to go once you identify true TDC.

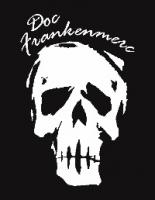

By 'true TDC' I mean the center of TDC, not the beginning of TDC when the piston stops coming up, but the half-way point between that and when the piston begins to go down again.

The first picture explains how to locate true TDC - even at midnight in a foreign country.

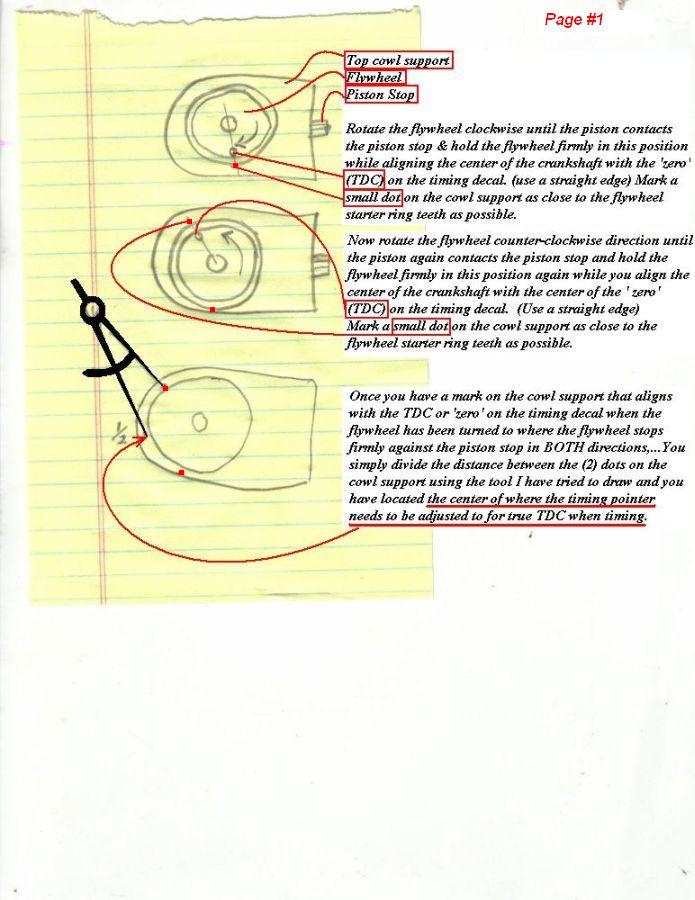

The second picture is of a 360 degree wheel. Believe it or not,...The diameter of the wheel can make a critical difference in the measurement of a degree. 8" is ideal for the common Merc inline-6 flywheel.

The third picture shows how to use a piece of a later top cowl support to identify degrees of advance.

It also shows what I mean by fabricating by use of a piece of cardboard in lieu of a dwell wheel or top cowl support when armed with the measurement of degrees on an 8" circle.

It also shows the one and only flywheel style decal by Merc to show TDC, BTDC & ATDC when used on the flywheel with a vertical surface, flex-plate, & center hub.

Please write direct if you can simply use the decal, or if you want to borrow the piece of top cowl support or cardboard cut-out.

I attempted to call today, but I was unable to understand the language or name of the receiver.

Doc F