Matt,

The early 800 4 cyl might have (10) powerhead studs rather than the more common (8) count.

There might be (2) at the aft end that are smaller (5/16" studs with a 1/2" wrench required to remove the nuts.

Once you are sure you have all the nuts removed:

(8) 9/16" wrench required

and maybe

(2) more 1/2" wrench required

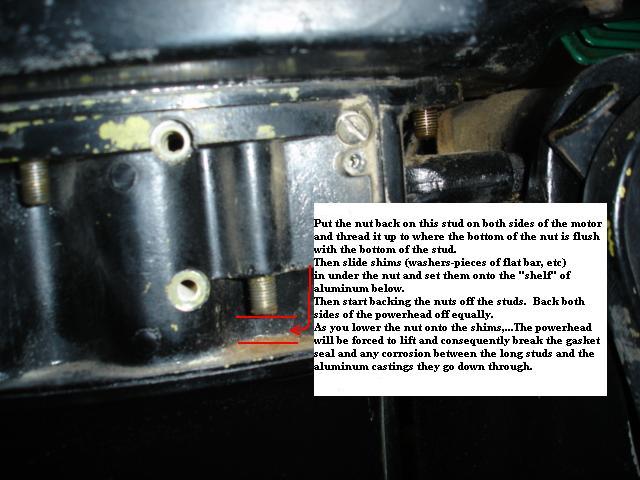

Then follow the instructions in the attached pictures to get the powerhead to break loose so you can lift it with a hoist.

One of the pictures mentions seeing more details in ome of my 'Tech Docs' so I have cut-n-pasted that info here, but some of the problems mentioned may not apply in your case as this was written for an extremely salted dog removal:

It sounds like either or both the shift shaft coupler & the driveshaft into the crankshaft might be corroded and seized together.

In this case I would 'push' the lower unit off by replacing the nyloc nuts with flat surface nuts at the two forward side studs. Then thread these nuts onto the studs until the top of the nuts are flush with the top of the studs and then stack spacer material between the top side of these nuts and the lower until directly above these nuts.

I use pieces of flat bar aluminum or steel for the spacer material. I have used large washers too, but you have to be sure the nuts don't align with the center holes of these washers by only sliding the washer into the area so the nut will be pushing up on the actual washer steel - not the center hole (make sense - or need a picture?)

Then start backing off these nuts. As the nuts raise they will be forced to try and push the lower unit away from the studs.

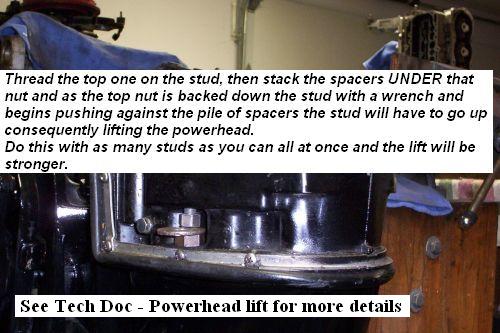

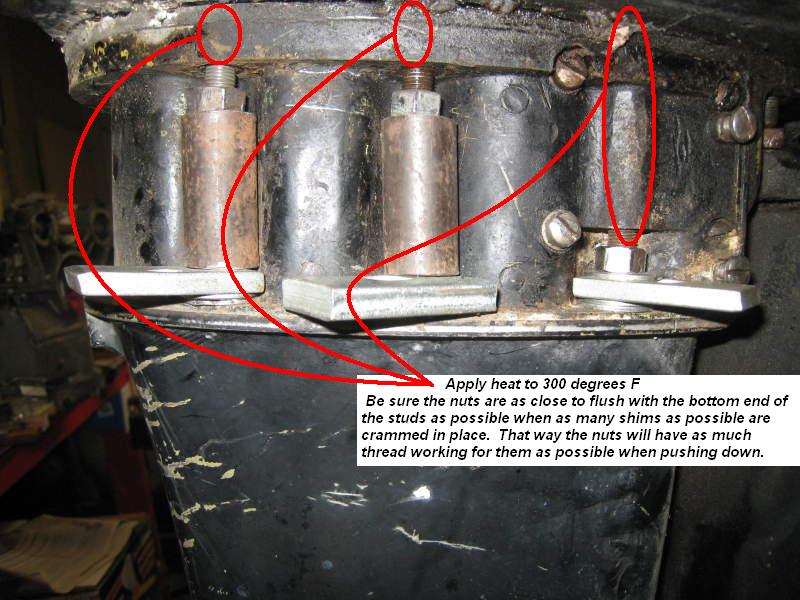

Then,....Once I get these two assemblies are pushing quite firmly - stop and set up similar set-ups on at least two power head studs per side and begin applying pressure there too - forcing these upper nut and related spacer assemblies to push the studs and power head up and separate from the top of the DSH.

When you then keep backing off all of these nuts equally things should separate. If you back the nuts off to where they are running out of threads on their respective studs - simply stop & run the nut back up onto the remaining studs a bit and slip in more spacer material and begin the separation pushing again.

Hopefully the attached pictures will help with the explanation, but if not - no worries - I can take more pictures.

Don't hesitate to apply heat to the surrounding aluminum casting at the same time as there is always the possibility that the studs are seized in the aluminum - but I'm guessing your driveshaft or shift shaft are seized if you have been able to separate things an eighth inch or so and things don't start separating.

Thom