Here is an explanation of how to do a Leak Down Test.

I'm not the author & don't recall who is.

"Performing a Leak-Down Test

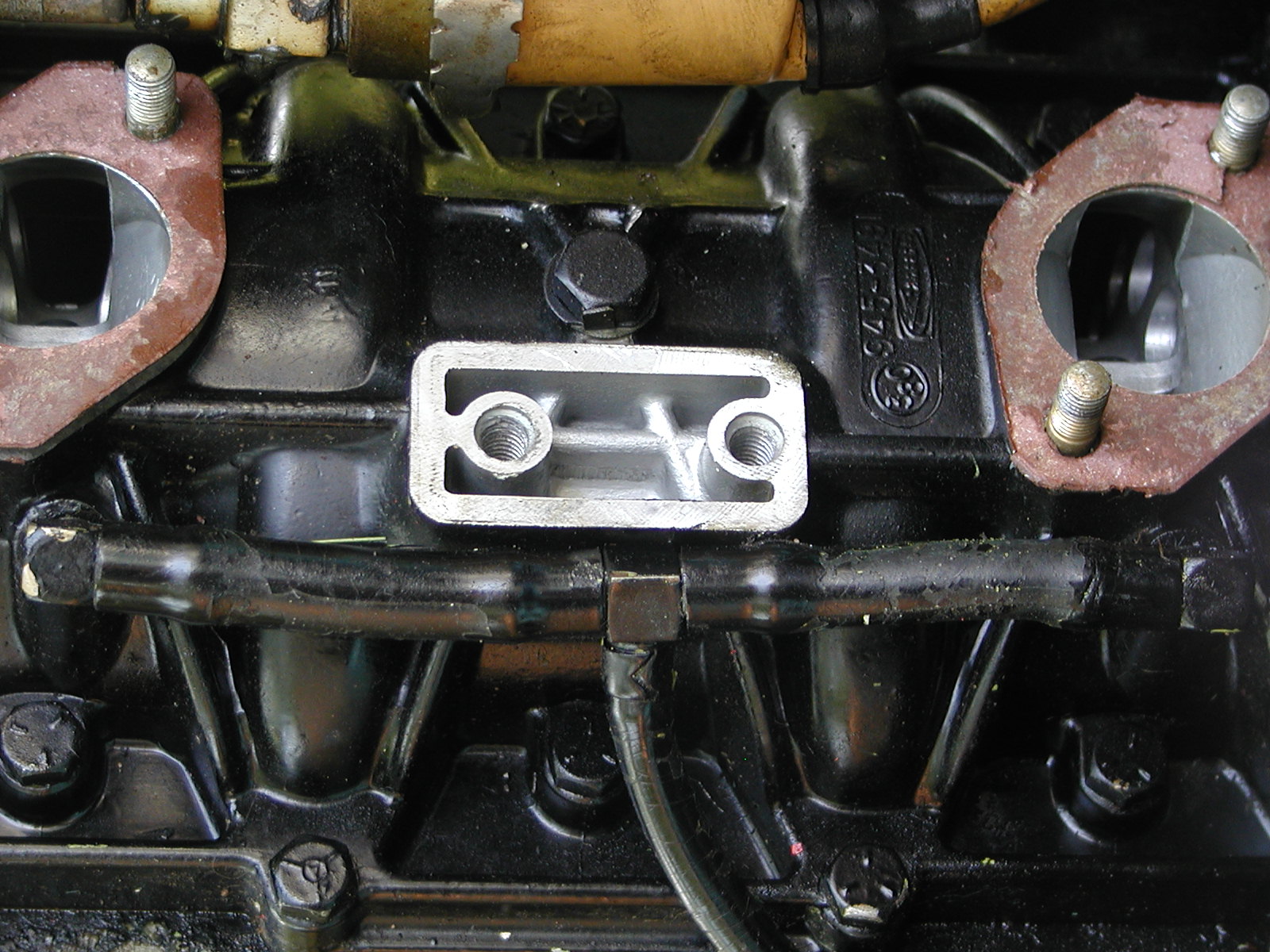

First off you'll need the tool which consists of (2) gauges with a one-way check valve between them and a hose off the second gauge that will thread snuggly into a sparkplug hole (like a compression gauge hose) There needs to be a dump valve on this secondary line too so that you can dump air pressure safely once the test is completed.

Off the primary gauge (air IN side of the one-way valve) you'll need another air hose with a quick-release fitting consistent with your shop air supply and an "off-on" air valve at the intake port of this primary gauge to control air volume (psi) intake.

The gauges need to read 100 psi in 2 lb divisions. (This makes the math to determine percent of leak-down very simple)

The tool can be purchased to insure correct function.

Precision Mfg. & Sales Co., Inc.

1-800-237-5947

Tool Part Number CL-36

Then you'll need to ground the ignition to insure the beast doesn't try and spark.

(even though the spark plugs are all removed,…The ignition can go crazy just laying around and potentially ruin some expensive ignition components).

Then you can put a good socket on your long flex-bar onto the flywheel retaining nut so that you can get a real good grip and maintain control over the crankshaft's attempts to rotate as you apply air pressure.

This is a VERY DANGEROUS process if you don't do it correctly because if that big old flex-bar gets away from you it could swing around off compression and kill you.

Try and get the piston you are testing up near top-dead-center (TDC) (just before-not on TDC)

The piston definitely has to be above the ports at least.

Get a strong grip on the flex-bar and apply some air pressure. Try around 20-30 psi and see if you can control that amount.

Slowly rotate the crankshaft by use of the flex-bar moving toward TDC. At TDC you will find there is not as much resistance on the flex-bar and if you go too far and the piston starts continuing and going down the pressure on the flex-bar will now gain again, but will be pushing the flex-bar forward rather than back as it had been before you reached TDC. Make sense??

Anyway,...Find TDC and get a good grip on the flex-bar in a way that keeps it from taking off either clockwise or counter-clockwise as you apply air pressure.

Watching the primary gauge as you open the off-on valve - bring the air pressure up to 100 psi.

The secondary gauge should momentarily read 100 psi too,...But will fall off a few psi as the rings "leak-by".

The trick here is to try and keep the primary gauge reading 100 psi (more air will need to be applied as the secondary gauge bleeds off) and see just how much psi is seemingly consistent on the secondary gauge with the primary gauge maintaining 100 psi.

Example: If the secondary gauge seems to hold 97 psi pretty consistently with the primary gauge at 100 psi,...You have a 3 percent leak-down result for that cylinder at TDC.

Now,...If you have big hairy arms and are careful,...You can gently ease the crankshaft back (counter-clockwise) off TDC and do leak-down tests at different heights in the cylinder anywhere above the ports.

You can also bleed off the 100 psi,...Reposition the crankshaft to various heights - get a good grip on the flex-bar and bring the air pressure up again and conduct a leak-down test at that height in that cylinder.

Be CAREFUL."

In response to you reed question:

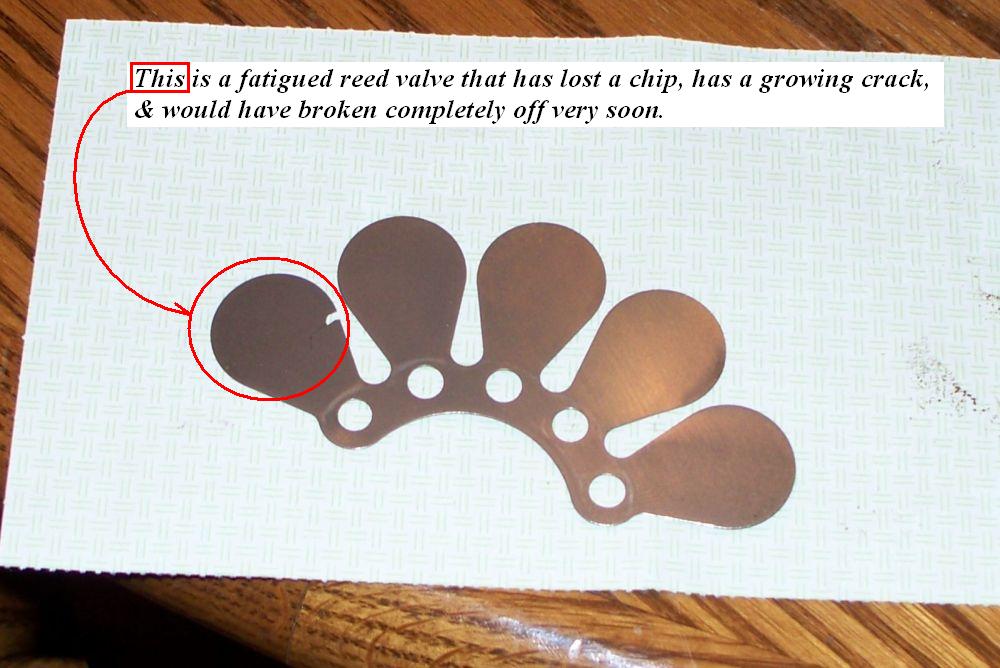

The actual reed valves are thin pieces of spring steel that open and close with crankcase pressure movement to let fuel mix in and then trap it in during the ignition.

A broken or chipped reed valve refers to one of these things having a crack, chip missing, or piece missing from fatigue or back-fire, etc.

This is not likely to be your problem as you would most likely see a bit of fuel spitting back out the carb with a poor idle condition.

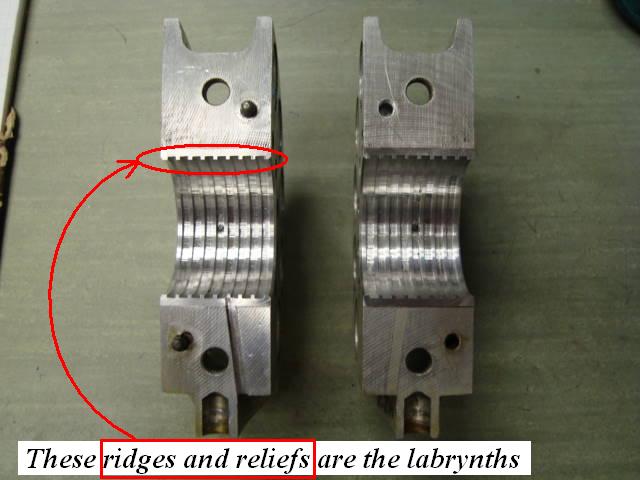

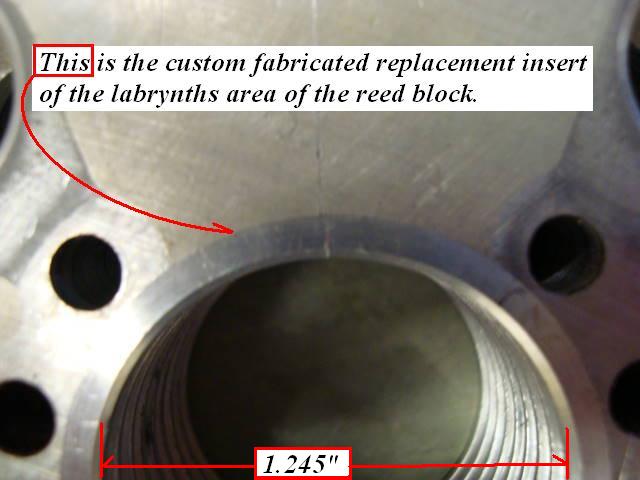

George was referencing the reed block labrynths being worn too much to restrict crankcase pressure exchanges between cylinders.

Armed with a micrometer you can check for excessive wear in the labrynths while the beast is disassembled and only while disassembled.

The inside diameter of the labrynth ridges that run against the crankshaft are 1.245".

Labrynths that cause a poor idle condition are worn by crankshaft flex, worn out main bearings, etc and will measure anywhere between 1.250" up to somewhere around 1.260+"

Any that measure between 1.245" - 1.249" will probably still provide a good idle condition.

I have them rebuilt or simply replace them with better condition used ones if they measure over 1.249".

The thing you want to watch for in swapping worn out reed blocks with good used ones from another Merc is to make sure the reed stops measure the same opening limit as the originals.

Without consulting the manual for an exact measurement for the 800 4 cyl in your serial range I'm guessing your reed stop openings will be listed somewhere around .155" and maybe as much as .170"

Thom