Shane,

I don't think anyone answered one question: How to get at the flywheel.

After you remove the faceplate (spring loaded knob at the bottom needs a 1/4 turn to release the face) and the wrap (two releases on the front),...You will see a black release sticking down at the center of the front of the black top hat.

Trip that lever by pulling out on the bottom.

Then lift the top hat at the front to about 45 degrees. This will be enough to allow you to lift the top hat as you slightly move it aft.

Then the flywheel will be visible.

In the center might be a yellow rubbery plastic hole cover. Pry it out with a small screw driver and you will find the flywheel nut.

It requires a 15/16" socket.

The advantage gained in use of Marvel Mystery Oil over common oil is that its molectular structure is smaller and consequently penetrates deeper and faster than common oil.

I'm not real sure what it is made of - perhaps ATF & kerosene???, but it is worth every penny.

Caution in taking the time to carefully allow lube to get down the sides of the pistons before attempting to turn the flywheel after such a long lay-up will help avoid unneccesary scoring that can be caused by dry rings moving across dry cylinder walls or cylinder walls with a patina of rust from years of ambient moisture being allowed to collect in the beast.

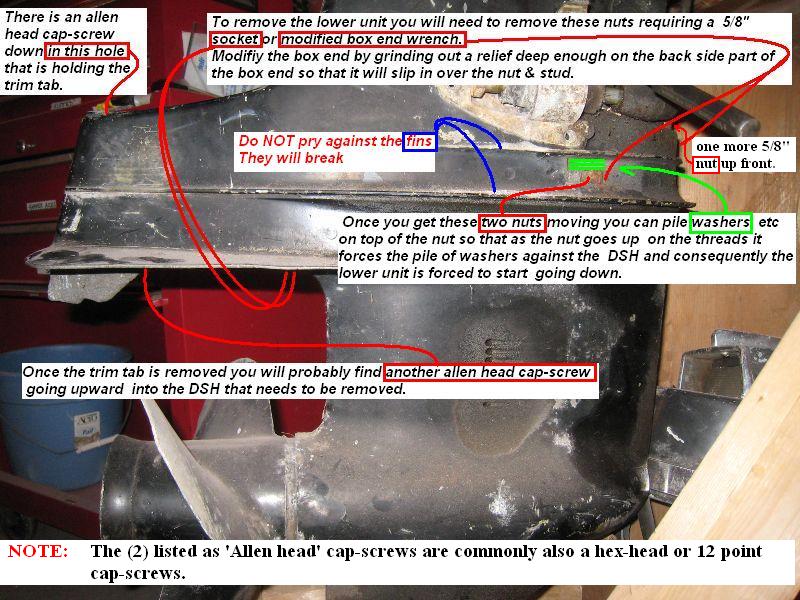

IF you find that the flywheel won't turn (and other than gentle rocking back-n-forth only turn it clockwise to avoid damage to the water pump's impeller),...It is time to remove the lower unit (gear case) so you can determine if the pistons are seized or if the lower unit is seized (more common in neglected outboards that a dry seized powerhead).

I have attached a picture with instructions to remove the lower unit.

Granted,...Concern for the old water pump impeller at this time is not neccesary as you will definitely want to install a new impeller before you're finished, but it is good practice to NEVER turn a flywheel counter-clockwise so that when it does matter you will already have yourself trained.

It is possible that the old ignition switch still has a three digit number on a white sticker attached to it. That is the Mercury key number required.

The wiring is commonly thrashed. In some cases they can be cut back to somewhat decent wire and re-soldered to the ignition switch for function as you determine whether or not you have reason to later spend good money on new wiring, etc.

Once you get the powerhead to turn smoothly - check in so we can explain the critical steps required to check compressions, test for spark, etc, etc, without damaging valuable components that are getting scarcer and scarcer.

Thom