update on the '67 950 SS resurrection. acquired a boat two years ago with a 950SS motor on it that had been sitting in a garage since 2007. estimated total run time 200 hours. pulled the plugs, sprayed with deep creep, let sit for a bit, turned over on starter w/no coil hooked up, spun eagerly. pressurized fuel system with bulb.....leaked everywhere. rebuilt fuel pumps, replaced fuel lines with new 1/4" line under the cowling. new inline filter between tank and bulb. replaced pump impeller, replaced seals in LU. motor started right up on land with muffs. ran the boat on the lake.....I run 90-92 octane rec fuel only....got 4k+ rpm out of it for a bit then started cutting out to full stall. suspected fuel starvation/dirty filters in tank etc. replaced fuel line from tank to motor with 5/16" in line, cleaned out tank and pick up tube screen. new inline filter also. boat ran well on lake at higher rpm but did not like to idle and was hard to start after it died. did not cut out at wot and was up around 4k+ or better. am running the stock 2 blade prop specd' for that motor/boat combo. put the boat away for the winter.....the only prep was fuel stabilizer in tank, drain and refill LU and deep creep in cylinders in a climate that gets sub zero in the winter. couldn't find any info as to running antifreeze through the system as a precaution. Put the boat on the water this spring and was somewhat difficult to start and could not get more than a stumbling 3500 rpm out of motor. was hard to start (need choke and warm up lever) suspected dirty/worn carbs and did partial rebuilds. my lazy/impatient self only cleaned filters (HUGE amount of "coffee grounds" in filters in carbs but the screens themselves and bowls etc were in amazing shape.....very little, if any, "corrosion". also did new float needles and seats but not idle screws, primary jets or any other repairs/inspection. kicking myself now......its the "not knowing" that eats me.....cant believe I let that stuff slide. also, at this time I increased the fuel diameter under the cowling to 5/16" with all new larger fittings. Also repaired any and all rotted/cracked wiring for ignition system under the cowling. pulled the plugs, they were pretty heavily fouled/wet and I could see caked carbon on the piston faces. checked the compression and got 130 on all cylinders with the motor in neutral/idle positon on the gear selector.......not sure how to get wot without engaging the prop with the selector?? help on that? wire brushed the plugs reinstalled. dropped the lower unit to inspect the pump/impeller (the previous season I had observed LARGE amount of slimy brown sludge exiting the prop/exhaust area smelling heavily of fuel and oil rather than gear oil. reinstalled the lower unit and fired the motor on the muffs. no water from tell tale. was not satisfied that the muffs provided a good source of water so dunked the unit in a barrel and fired......positive tell tale stream. motor ran well at low rpm. was able to shut off and restart with just a touch of the key. observed a lot of smoke and considerable gunky oily discharge coming to the surface of the barrel. felt the surface temp of various locations on the block while running in the barrel and all seemed cool to cold depending of where I was on the block. the cylinder walls all felt the same top to bottom.....was more a left side/right side difference. 2 stroke eco terrorism..... ran the boat on the lake after that and am able to get 4k rpm. removed the cowling on the water to do idle adjustments according to seloc manual.....not quite satisfied with the way that ended up and, indeed, the motor still stalls periodically at idle and is hard to start. runs far better without cowling on although is deafening. since acquiring the motor ive noticed a dried "tar like" substance running down the block at the seam of the crank case and the block. I assumed it was lacquered fuel from sitting that had oozed or decomposed gasket cement or something. when I run the motor without the cowling, I can now see fuel hissing and seeping at this joint on the starboard side of the block. not "spraying" out but definitely leaking at this joint. manual does not show a gasket here....???? seems crazy. I would like to pull carbs again and do idle needles and a full rebuild and am wondering if I can remove the crankcase cover from the block and clean/glue it back on without further disassembly or removal of the powerhead from the driveshaft housing; can I just unbolt the 20 some odd bolts and get the cover off with out disturbing the end caps or is it all pinned together by something other than the case cover fastening bolts?......manual is unclear on this. do not seem to be getting any excess fuel leaking from carbs as previously and ran my finger around the inside of the carb throats to "see" what I got. I noticed a slight silver/grey color to the fuel residue there; almost anti seize like.....as if aluminum was being worn somewhere and showing up in the fuel in carb throats. most evident on carb 2 (center). not sure what thats about. when I reinstalled the carbs on the crank case I used a very light, thin (surgical amount) of permatex on the gaskets to hold in place etc.....as I have on many engine overhauls/rebuilds and was very careful not to contaminate the interior edges of the case/carb area. I can't imagine its grey permatex im seeing in the fuel......has more of a metallic sheen to it which alarms me. also noticed really dirty/sloppy machining/casting work between carbs and case......would LOVE to gasket match, port and polish!!!!

Really sorry about the rambling, multi subject post......any and all thoughts and suggestions/criticisms are taken positively and appreciated. The motor and boat are in fantastic condition and am just trying not to do any un necessary damage through negligence.

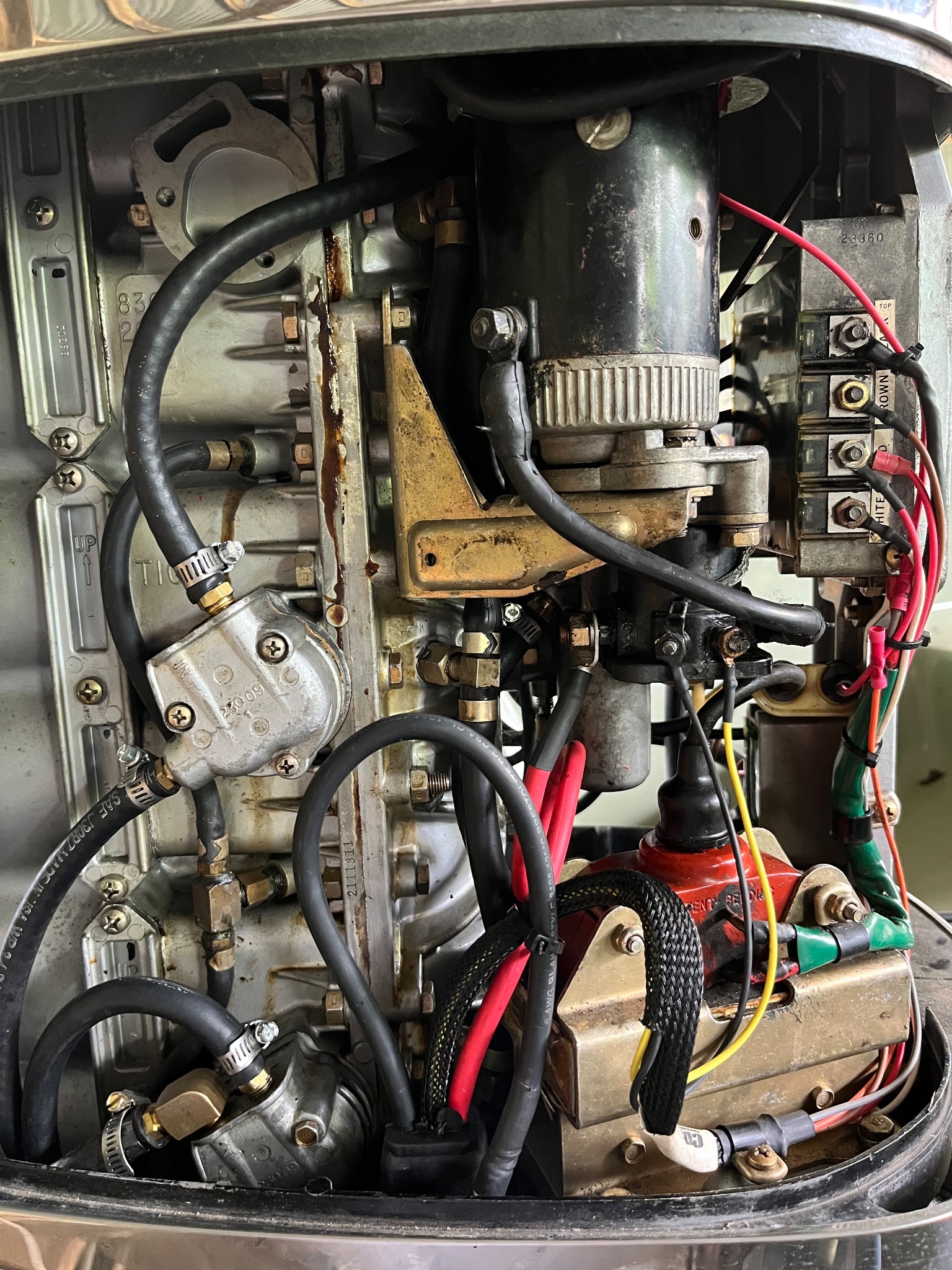

also......would it be worth removing the balance tubes and check valves on the crankcase to clean/inspect? Replaced hoses and fittings?? what exactly does that system do.....??? I've posted a photo of the stripped case cover......does anything look suspicious? im a little concerned with the difference in the surface appearance of the upper vs lower crankcase cover. To me, the upper portions of the case cover looked "stressed" , while the lower portions of the cover look, as we used to say, "sano"